Ensure optimal performance and effective heating with Hi-Watt’s mica band heaters. This type of heater is made with mica, which is an exceptional electrical insulator. The mica is wound with wire and then bent into a circle. There are a wide array of benefits to this type of heater, including its high-watt density, lifetime expectancy, and temperature capabilities (up to 900 degrees Fahrenheit).

Hi-Watt is proud to sell high-quality mica band heaters from brands like Backer Marathon. Backer Marathon mica band heaters are entirely computer-designed, and they come in a wide array of designs, making it easy to find one that best meets your needs.

Construction

As a trusted mica band heater supplier, we only partner with brands that we know and trust. To ensure better performance, Backer Marathon only uses the most high quality materials available on the market.

Some of the main features of band heaters include:

- Metal Sheath: Designed to resist oxidation and withstand high temperatures.

- Mica Insulation: Provides exceptional moisture resistance and electrical insulation, especially at high temperatures up to 900 degrees.

- Stainless Steel Clamping Band: Can maintain clamping pressure, even at high temperatures.

- Resistance Wire: Made with nickel and chromium and designed to provide uniform heat distribution.

- Special construction options include expandable, two-piece designs and custom cutouts.

Options for Mica Heating Bands

At Hi-Watt, we know that every client has unique needs. That’s why we offer a variety of termination and clamping options for all mica band heater designs. Our termination options include fiberglass, stainless steel braid, and post-terminal, and our clamping options include straps, wedges, flanges, spring-loaded, and welded-on barrel nuts. Read below for more details on each option.

Termination Options

Because electrical connectors are an essential component of any electrical system, it’s important to choose the right one. You will need to consider the operating conditions, any weight and cost restrictions, the frequency at which the heater will be used, and more. Hi-Watt currently offers four different connector/termination options:

- Fiberglass Lead: Classified as 550 degrees Celsius wire.

- Stainless Steel Braid Stainless Steel Conduit (Armor Cable/Hose)

- Post-Terminal: This termination option allows you to screw on nuts or other parts.

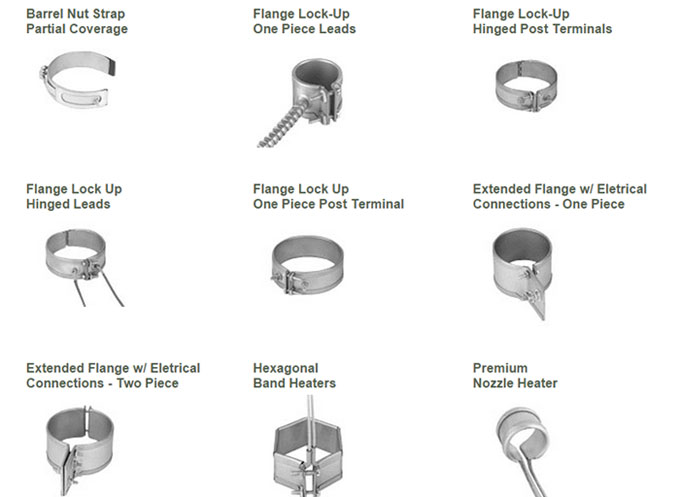

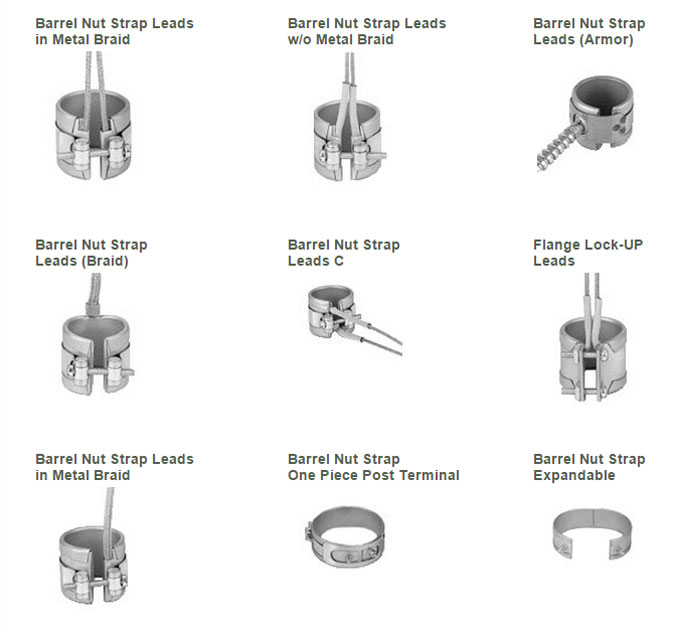

Mica Heater Clamping Options:

Select the right clamping solution with help from our experts at Hi-Watt. We offer several types of clamping options:

- Strap: Straps have low thermal expansion, meaning that they tighten around the heater’s entire circumference, ensuring optimal contact between the working surface and the heater.

- Welded-on Barrel Nuts: We offer welded-on barrel nuts as an option on any lead or screw termination. Barrel nuts work particularly well with heaters that include cutouts or holes.

- Wedge: Wedges are optimal for heaters that are placed in hard-to-access locations.

- Flange Lock-up: Just like barrel nuts, flanges work well for heaters that have multiple holes.

- Spring-Loaded Clamping: This type of clamp is the easiest to install/connect and is guaranteed to retain tightness during the start-up process.

Common Mica Heater Termination and Clamping Options:

Watt Density

The maximum allowable watt density for your heater depends on the cylinder temperature. Please consult the table below for more information.

| Maximum Allowable Watt Density |

| Cylinder Temperature (Degrees Fahrenheit) | 200 Degrees Fahrenheit | 300 Degrees Fahrenheit | 400 Degrees Fahrenheit | 500 Degrees Fahrenheit | 600 Degrees Fahrenheit | 700 Degrees Fahrenheit | 800 Degrees Fahrenheit |

| I.D.t: 1.5” to 3” | 52 | 51 | 50 | 46 | 41 | 37 | 29 |

| I.D.: 3” to 10” | 47 | 46 | 45 | 42 | 38 | 33 | 25 |

| I.D.: 10” and up | 41 | 40 | 39 | 36 | 31 | 27 | 20 |

Application Safety & Performance Guidelines

To ensure optimal performance of your mica band heater, we recommend the following guidelines:

- Do not exceed the maximum sheath temperature (900 degrees Fahrenheit).

- Make sure your heater is installed on a smooth, flat surface.

- Do not open the heater during installation.

- Ensure your clamping band is as tight as possible before turning on the heater.

- Make sure the diameter of your heater is appropriate for your application.

- Retighten clamps after use, once they’re cooled down.

- Do not exceed 20 newton-pounds of torque when using post-terminal nuts.

- Place your heater in an area that is as far away from contaminants as possible.

- Avoid getting your heater wet or moist.

Speak with an expert

Over last 8 years we have addressed 95% of inside sales quoting requests within 3 hours.