We stock robust thermowells featuring thick walls and sturdy construction. They withstand the effects of high-pressure processing and high velocity flows. Thermowells are protective receptacles that shield temperature measuring devices, such as thermocouple sensors and RTD sensors, from the negative effects that may occur through process immersion and exposure. They encase the sensing element, allowing it to be inserted into a vessel or pipe.

The industrial temperature sensor in a thermowell continues to maintain sensitivity and functionality. Our industrial thermowells from leading manufacturers are produced from drilled-out bar stock. The tubes create a pressure-tight connection at the point of installation. The receptacle may be categorized based on its type of process connection, as in a flanged or threaded thermocouple.

Thermowell vs Thermocouple Tubes

A thermowell delivers a smart solution to making a sensor compatible with a variety of industrial/commercial conditions when it otherwise would not have compatibility. The metal thermowells support high thermal conductivity and rapid readings. We stock the most popular thermowell designs and can also assist with custom-made products. Also consider our ceramic thermocouple tubes that are resistant to corrosion, abrasion, oxidation, and deformation.

Thermowells and Protection Tube Spec Sheet

Selecting Sensor Protection Tubes

When a pressurized fit is not essential, a sensor protection tube can offer another method of safeguarding sensing devices. These pipe-shaped receptacles are economical, low-maintenance alternatives to the thermowell. Both ceramic and metal (pipe type) protecting tubes protect the temperature sensor from harsh environments.

Unlike thermowells, they are not primarily designed for pressure-tight applications. The tubes are commonly used in heat treatment furnaces, ovens, ducts, and other applications. Processes with corrosive effects will require corrosion-resistant materials, such as those found in coated and ceramic protective tubes.

Our tubes for sensors come with corrosion resistance, thermal shock resistance, and strong construction for longer lives. Leading-edge designs support fast readings and low maintenance.

Protecting tube construction styles are more limited than thermowells. The tubes offer the advantages of economy, corrosion resistance, and, in some cases, higher temperature capabilities. Contact our knowledgeable staff to learn about encasing essential sensors in a thermowell or protective tube.

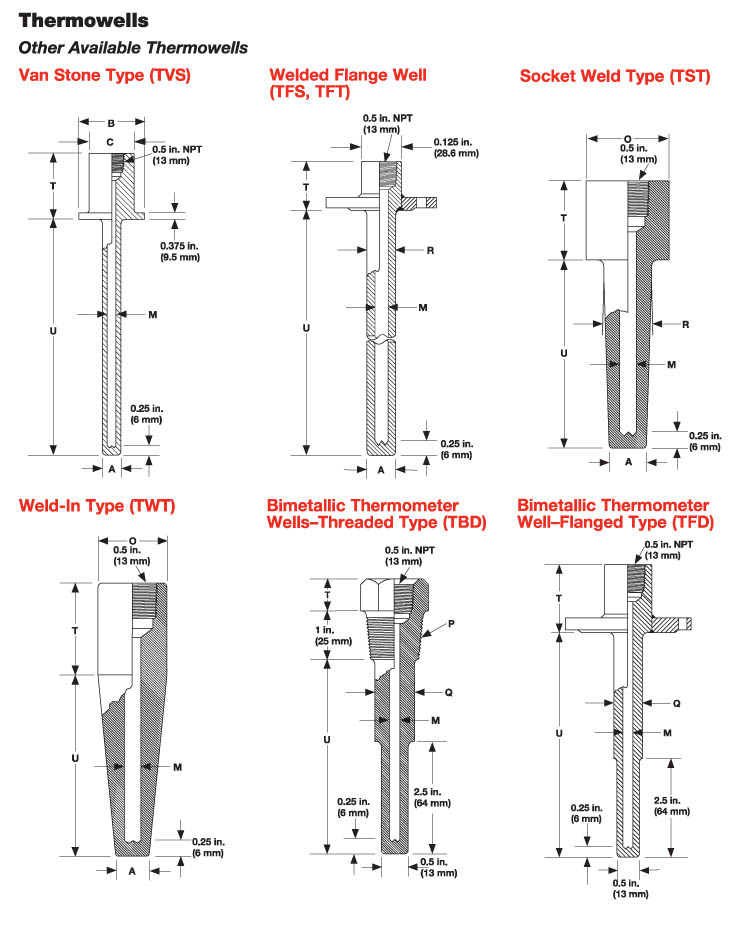

Other Available Thermowell Sensors

Other available thermowells include Van Stone Type (TVS), Welded Flange Well (TFS, TFT), Socket Weld Type (TST), Weld-In Type (TWT), Bimetallic Thermometer Wells-Threaded Type (TBD), Bimetallic Thermometer Well-Flanged Type (TFD), and Pipe Type.

Speak with an expert

Over last 8 years we have addressed 95% of inside sales quoting requests within 3 hours.