The Importance of Thermal Blankets & Boards

Thermal insulation, including blankets and boards, is commonly used to cover and protect industrial equipment, manifolds, pipes, valves, extruders, and other components to conserve thermal energy and generate energy cost savings. Additionally, insulation prevents freezing, seizing, or other adverse conditions. They also protect workers from burn injury or heat fatigue from high-temperature equipment.

Although industrial facilities and processes require thermal protection to prevent equipment failure and workplace injuries, it’s important to note that there is no universal thermal insulation solution or product. The type of thermal protection you’ll need will depend on your application. Below, we’ll outline the two most common types of insulation: thermal blankets and thermal boards, their common uses, and how to select the best one for your needs.

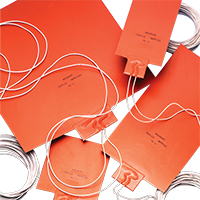

What Are Thermal Blankets?

Thermal blanket insulation, including thermal jackets, is a passive type of thermal control that covers equipment, pipes, or valves. It’s typically a roll of fiberglass-, mica-, or silica-based material designed to trap air and slow the transfer of heat. Depending on the material and thickness of the thermal blanket, they can withstand temperatures from 500 up to 1,800 degrees Fahrenheit or more. Thermal blankets are also available in various sizes to cover equipment with a unique geometry or large footprint.

Thermal jackets are a versatile solution for covering standard-sized pipes, vessels, or OEM equipment. Additionally, thermal blankets can generate substantiation energy cost savings

What Are Thermal Boards?

A thermal board is a cost-effective way to insulate hot or cold applications. It is especially useful when equipment may be vulnerable to heat losses and it is non-cylindrical (like industrial tooling, ovens, kilns, and furnaces) or has an unusual geometry. The thermal board’s rigid ceramic or mineral wool fiber material is made to insulate against extremely high temperatures and offers both thermal and sound reduction.

For manufacturing equipment or process areas causing extremely high ambient temperatures, thermal boards can reduce interior air temperatures and protect employees from heat-related incidents.

Applications

The plastic injection molding and extrusion industries commonly rely on thermal blanket insulation. Plastic processing equipment operates at extremely high temperatures, and any heat that escapes can impact the cost of production. Thermal blankets are used to cover the melt pipes, manifolds, and extruders on plastic injection molding equipment.

Other industrial applications that need thermal protection to operate efficiently include petrochemical processing facilities, marine and aerospace operations, LNG/oil/gas processes, power generation, agriculture, and any industrial fluid facility where process pipes are run outdoors, like breweries and distilleries.

Choosing the Right Thermal Insulation Covering

When choosing between thermal blankets and boards, you must first consider the application and temperature requirements. Different material types and thicknesses are best suited for different temperature applications.

When space is limited, or system controls need to be protected, a thinner thermal board or more flexible thermal blankets should be considered.

Lastly, always evaluate the equipment and whether it will be exposed to chemicals, water, debris, UV radiation, or outdoor elements.

Get Thermal Blankets & Boards From Hi-Watt Today

Hi-Watt can help you find a thermal blanket or board that meets fire retardancy, OSHA safety, and other industry regulatory requirements. Founded in 1979, we’re a trusted industrial heating solution provider serving manufacturers across Michigan. In addition to selling thermal products from brands like Watlow, Chromalox, and Tempco, we can also design and build custom solutions.

Contact us today to learn more about our capabilities or to schedule a consultation with one of our experts.