How to Configure Your Thermocouple

When precision matters in industrial heating applications, you need a custom thermocouple. Unlike off-the-shelf models, custom thermocouples are designed to meet exacting requirements in terms of length, material, temperature range, and environmental compatibility, ensuring more accurate and reliable readings.

If you’re trying to configure a custom thermocouple, keep reading this guide. In it, we’ll discuss how to use our configurator and detail some of the factors you will need to customize.

Diameter

Hi-Watt offers multiple diameter options. The diameter impacts the sensor’s response time and durability, with thinner diameters providing quicker responses to temperature changes but less durability under mechanical stress or in harsh environments.

When determining diameter, consider your environment and if rapid temperature changes are expected. Balancing between response and durability can be challenging, so don’t hesitate to contact one of our application specialists at (855) 467-5628 for assistance.

Style

Hi-Watt supplies several common thermocouple styles, including Bayonet, Washer, Hose Clamp, Probe, Shim, and Nozzle. We’ve broken down each type below. If you don’t see a style/physical setup you’re looking for, contact us at (855) 467-5628 to learn more about other styles we can accommodate.

Bayonet

This thermocouple style features a spring-loaded tip that makes installation and removal quick and easy and a bayonet cap that locks into an adapter. It’s ideal for plastic injection molding machines or essentially any application where the thermocouple would need to be frequently replaced or adjusted. A Bayonet-style thermocouple may not provide as secure a fit as more permanently mounted styles.

Washer

As the name suggests, washer-style thermocouples are flat and fit between two surfaces. They’re great for measuring surface temperatures, particularly in applications where space is limited, like engine blocks or heating elements.

Hose Clamp

This style is primarily used for applications that require the thermocouple to be attached to pipes or hoses for temperature measurements, like HVAC systems or process piping. Hose clamp thermocouples are easy to install and adjust in non-invasive applications as they don’t require drilling or welding. However, they do not provide as tight a contact as other styles.

Probe

Probes are the most common type of thermocouple style featuring a rigid or flexible sheath that houses the thermocouple elements. This style is extremely versatile, as it can be used to measure liquids, gases, and semi-solid materials, and its direct contact ensures accurate internal temperature readings. Keep in mind that this style requires pre-drilled holes or ports.

Shim

This type of thermocouple is thin and designed to be inserted into gaps or under surfaces. It’s commonly used to detect temperature variations along surfaces or in confined spaces, such as in laminate presses or under heavy machinery.

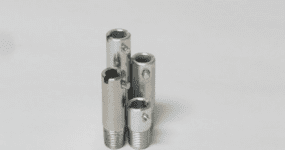

Nozzle

Lastly, nozzle thermocouples are specifically designed to fit into the nozzles of injection molding machines or similar equipment, so they are only limited to applications with nozzles.

Calibration Type

Hi-Watt provides many calibration types, including three of the most common: J, K, and T.

Type J

Type J thermocouples are composed of iron and constantan, making them suitable for temperature ranges between -40 and 1,382 degrees Fahrenheit. They shouldn’t be used in sulfur-containing environments, as iron is susceptible to corrosion, but they are ideal for vacuuming, oxidizing, reducing, and inert atmospheres. They’re also more stable than Type K at lower temperatures, but have a limited upper-temperature range compared to Type K, so they’re not suitable for higher-temperature applications.

Type K

Type K thermocouples contain chromel and alumel and are recommended for high-temperature applications, such as furnaces, gas turbine exhaust, and diesel engines. They’re suitable in temperatures up to 2,282 degrees Fahrenheit, but they can be susceptible to oxidation at high temperatures and can be affected by magnetic fields when heated above 662 degrees Fahrenheit.

Type K thermocouples contain chromel and alumel and are recommended for high-temperature applications, such as furnaces, gas turbine exhaust, and diesel engines. They’re suitable in temperatures up to 2,282 degrees Fahrenheit, but they can be susceptible to oxidation at high temperatures and can be affected by magnetic fields when heated above 662 degrees Fahrenheit.

Type T

Type T thermocouples are made from copper and constantan. They are highly stable and accurate for lower-temperature applications (between -328 and 662 degrees Fahrenheit). This calibration type is particularly useful in lower-temperature applications and in moist environments.

Junction Type

You’ll also need to choose between grounded and ungrounded thermocouples.

In a grounded junction, the thermocouple is physically attached to the inside of the protective sheath. Due to the direct contact with the sheath, grounded junctions typically respond quicker to rapid temperature changes. However, since the junction is in direct contact with the sheath, it can be more susceptible to electrical noise and interference. It can also cause grounding issues if the sheath isn’t properly isolated from the rest of the equipment.

Comparatively, ungrounded thermocouples are insulated from the protective sheath, so there’s no direct contact between the junction and the sheath. This insulation provides better isolation from electrical noise and interference and reduces the risk of accidental grounding, which can be important in sensitive/high-stakes applications or environments with high electrical noise.

When choosing between these two, consider your application’s response time needs, environmental conditions, and any safety or grounding concerns.

Lead Length

Next, determine the lead length you need. Inaccurate lengths will impact measurement accuracy and signal quality.

You’ll want to measure the distance from where the thermocouple will be placed to where the signal will be read or controlled. Then, evaluate the path the leads will need to follow to reach the readout or controller. Do you need to account for any necessary detours around machinery or other obstructions? Are there high-EMI or high-temperature areas that could impact signal integrity or lead integrity?

Additionally, allow some extra length to make installation easier, as extra slack can help avoid tension in the wires that would lead to breakage or poor connections. You should also think about whether the leads will be exposed to varying temperatures, as materials could expand or contract, affecting the length.

When in doubt, contact one of our application specialists—they can help guide you on what lead length is best for your facility.

Lead Material

When selecting your thermocouple’s lead material, the choice often comes down to temperature resistance, environmental conditions, and application requirements.

We primarily offer two materials: fiberglass and Teflon. However, other material options are available upon request (please list lead material requests outside of fiberglass and Teflon in the configurator’s ‘Special Requests’ section).

Fiberglass

Fiberglass is recommended for high-temperature applications, as it can withstand temperatures up to about 932 degrees Fahrenheit. It’s also resistant to many chemicals and is suitable for harsh conditions.

On the other hand, fiberglass is less flexible than Teflon, which can make installation in tight or complex configurations more challenging. Fiberglass can also absorb moisture, making it less suitable for damp or humid environments.

Recommend Environments/Applications

- High-temperature

- Dry

- Some harsh environments

Teflon

Teflon is the best choice for harsh environments as it’s highly resistant to almost all industrial chemicals. It also doesn’t absorb water like fiberglass, so it won’t degrade in humid or moist conditions. Its flexibility also makes it great for small or limited spaces.

The downside of Teflon is that it’s not as suitable for high-temperature applications, as it can only withstand up to 500 degrees Fahrenheit.

Recommended Environments/Applications

- Lower-temperature applications

- Chemical processing

- Humid/moist environments

- Small spaces

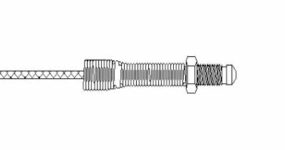

Protection

If your custom thermocouple will be placed in a harsh environment, we recommend adding protection. Protection, like armor cable and stainless steel overbraid, can reduce damage from machinery and moving parts, corrosive environments, and areas with high levels of electrical noise.

Armor cable protection provides excellent mechanical protection against crushing, cutting, and abrasion and offers decent electromagnetic interference shielding. However, it’s not as flexible as stainless steel and is usually heavy. Stainless steel overbraid is a better option for limited spaces, complicated/tight installations, and humid or corrosive environments.

Termination

Your termination option is vital for ensuring reliable connections to your monitoring and control systems. We offer several options: Split Leads, Spade Lugs, Standard Jack, Standard Plug, Mini Jack, and Mini Plug.

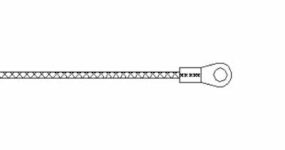

Split Leads

In this option, the wires are separated and stripped at the ends to allow for direct connection without additional connectors. While it may be more vulnerable to mechanical damage and corrosion, it can be great for custom installations where connections might need to be changed frequently or for direct integration into existing systems.

Spade Lugs

These metal spade-shaped connectors are attached to the ends of the leads, helping provide a reliable and secure mechanical connection that can be easily installed or removed. This option is slightly bulkier than other options, which might not be suitable for compact spaces. However, it’s ideal for industrial control systems that may require frequent disconnection and reconnection.

Standard Jack

Standard jacks are typically used with larger, standard-sized connectors and offer a secure and protected connection, minimizing any risk of accidental disconnection. This secure connection makes this option ideal for laboratory and testing environments. However, they’re bulky, so they may not be suited for tight spaces.

Standard Plug

Similar to a standard jack, a standard plug provides a stable and secure connection. Like standard plugs, they are bulky, so they’re appropriate for stationary setups where space is not a limiting factor.

Mini Jack

A mini-jack is a smaller version of the standard jack, providing a compact female connector for mini plugs. They’re great for portable devices or compact equipment setups.

Mini Plugs

Mini-plugs are a smaller version of a standard plug, designed to connect to a mini-jack. Like the mini-jack, they’re compact, convenient, and suitable for tight spaces and/or small setups that require robust connections.

Process Temperature

Process temperature is one of the most vital considerations when designing a thermocouple, as it influences the selection of calibration type, insulation and sheathing, and junction type. It also helps manufacturers understand if protective conduits or enclosures are needed, if the design needs to incorporate features that facilitate easy recalibration, and where the sensor should be located to prevent inaccurate readings.

When you input your process temperature into the configurator, our team can help you understand what other special requests may be needed or offer modifications to your selections to ensure your thermocouple is accurate and durable in your intended application.

Other Special Requests

Hi-Watt can also accommodate other special requests. Depending on your application and configurator responses, our application specialists may recommend additional modifications, including:

- A Hastelloy sheath for highly corrosive environments

- Dual calibration for applications requiring redundancy or in applications where different parts of a process operate in varying temperature ranges

- High-temperature connectors

- Double-insulated wire for extreme environments

- Color-coded wire, depending on safety or compliance requirements

- Custom brackets or mounts

- Additional sensors for backup or differential temperature measurement

- Integrated wireless transmission for remote monitoring or for locations that are challenging to access

If you’re not sure what to write in the ‘Special Requests’ section, please use this as an opportunity to discuss your application requirements.

Start Customizing Today

Based in Michigan, Hi-Watt is a regional supplier offering a wide range of thermal products, including stock and custom thermocouples, to facilities throughout the United States. Visit our website to use our configurator. If you need help customizing your thermocouple, contact our application specialists at (855) 467-5628 or complete our online form today.