Common Thermocouple Calibration Types

The relationship between the amount of voltage a thermocouple releases and the temperature it measures is not uniform across all thermocouples. Therefore, industrial temperature sensors each receive a calibration classification based on their EMF, ideal measuring medium, and temperature limits. Calibrations are denoted by letters and color coordination.

Each Watlow thermocouple follows the American Society for Testing and Materials’ calibration guidelines. Type T is rated for between -330 and 660 degrees Fahrenheit, but it can handle -452 degrees Fahrenheit, which is helium’s boiling point. Because Type T thermocouples can withstand such extreme cold, they are usually used for cryogenic applications.

Type N, which is made of a nickel alloy, is appropriate for oxidation and operates between 200 and 2300 degrees Fahrenheit. It stays accurate in the high limits of its temperatures, and it works well in environments with lots of sulfur.

K type thermocouples are also made of nickel and have the same temperature limits, but they are more commonly used than Type N thermocouple sensors. Particularly if you are performing a reduction chemical reaction, cover this thermocouple with a ceramic or metal sheath. Sheaths are not as critical during oxidation, but they do keep the thermocouple’s mechanical components clean.

J type thermocouples work well in dry, oxygen-poor environments, and in these conditions, they do not need sheaths. If you are measuring a medium that is over 1000 degrees Fahrenheit, choose wires with wide gauges to prevent iron oxidation. They operate between 200 and 1400 degrees Fahrenheit.

Finally, Type E thermocouples, which have the most popular calibration, work between 200 and 1650 degrees Fahrenheit. They can measure temperatures in vacuums, cryogenic environments, and environments where oxidation or reduction is occurring. Unlike many thermocouples, they do not corrode when exposed to extremely cold temperatures. Additionally, their ratio of EMF to degrees is the largest among normal calibrations, leading to quick results.

Features and Benefits

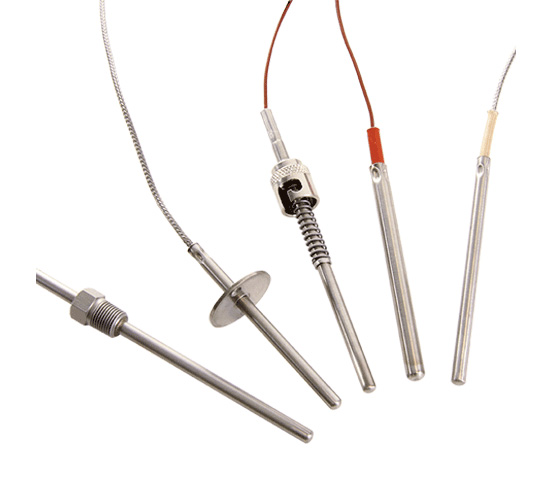

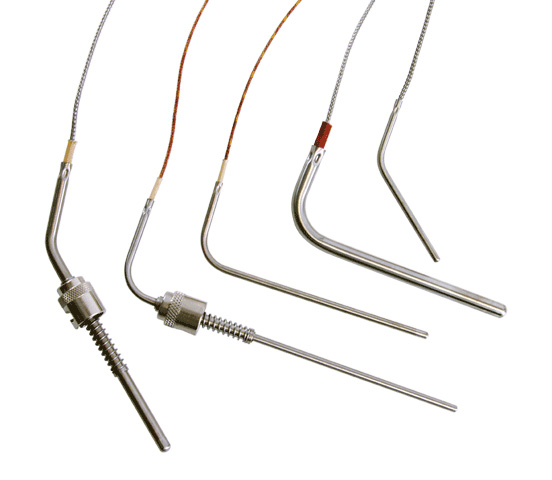

We offer Watlow thermocouples with Type E, J, K, and T calibrations, and we provide 32 different sheath lengths. Customize your wire junctions by grounding them or leaving them exposed, and choose lengths between 6 and 360 inches. Each purchase includes nozzles, clamps, and washers for easy installation, and you can choose thermocouples with 90-degree, 45-degree, or straight configurations.

Typical Applications

Watlow thermocouples are useful in any industry that needs heat control at extreme temperatures when normal thermometers are not appropriate. Applications include medical equipment manufacturing, heat treating, food production, and sanitary equipment packaging. These sensors are also useful for keeping refrigerators, ovens, and cooling baths at the right temperature.

Watlow Thermocouples

Mineral Insulated

Mineral insulated thermocouples feature methylglyoxal insulation that increases their ability to move heat to the broken junction. Made of XACTPAK, this model includes a sheath that allows the wires to have smaller diameters while still withstanding extreme temperatures. These smaller diameters also speed up the measuring process, which can take place at up to 2200 degrees Fahrenheit.

Tube and Wire

Tube and wire thermocouples rely on resin or fiberglass insulation and SERV-RITE wire to measure temperatures precisely and quickly. If you’re concerned about your wires’ security, we can add adjustable armor and a braided stainless steel wire to your product.

Sheathed

We also provide a sheath that preserves your measuring junction and keeps your thermocouple steady as you attach it to the medium you’re measuring. This thermocouple can handle up to 900 degrees Fahrenheit and is available in 0.125-, 0.1875-, or 0.25-in. diameters.

EXACTSENSE

EXACTSENSE thermocouples are ideal for combustion applications in which you need to check the temperature at multiple locations. We offer these thermocouples, which have three sensors, with Haynes 230, stainless steel, or alloy 600 sheaths.

High-Temperature

High-temperature thermocouples work well if you need Type B, R, or S calibrations that can handle extremely high temperatures. Their sheaths are made of exotic metals (highly specialized alloys) or noble metals (corrosion-resistant, naturally occurring metals), which allow the wires to maintain accurate readings at high temperatures. They remain accurate at 3100 degrees Fahrenheit and measure between 1.6 and 6.4 in. in diameter.

MICROCOIL

For the greatest level of accuracy in surface measuring, we recommend MICROCOIL thermocouples. These industrial temperature sensors can measure a medium’s surface without being affected by the exterior temperature thanks to their miniature size. They are rated for at most 1292 degrees Fahrenheit, and their exteriors have 0.125-in. diameters.

Multipoint

If you need to measure the temperature in several different locations of your medium at the same time, multipoint thermocouples are your best option. Multipoint thermocouples help you account for temperature gradients, especially when you need to ensure that your heating process is uniform across your medium’s depth and surface area. This product comes with six different temperature sensors that can handle up to 2200 degrees Fahrenheit. Each sensor measures 0.125, 0.1875, or 0.25 in. in diameter.

Industries that involve plasma production must rely on radio frequency measurements because normal temperature sensors do not work when exposed to plasma; however, when used improperly, it’s easy for RF measurements to be inaccurate. Watlow’s radio frequency thermocouples are optimized to handle the intense environment of plasma manufacturing while still delivering accurate results. These sensors are rated for 932 degrees Fahrenheit and measure 0.19 in. in diameter.

True Surface Thermocouples

If you need to measure the temperature of a flat surface, choose Watlow’s true surface thermocouples. Like MICROCOIL thermocouples, TSTs keep their measuring junctions separate from the exterior air, resulting in accurate readings with a 1% or 2% margin of error. Use normal screws to install your TSTs and have them measure your flat surfaces constantly, and use the molded cover to keep them safe in crowded locations. These thermocouples remain accurate for at most 400 degrees Fahrenheit.

Watlow Distributors

Based on your temperature and accuracy needs, choose the Watlow product that’s right for your business today.